When installing pallet racks, one of the most important factors to consider is whether they are on a level floor. An uneven surface makes it difficult for racks to stay vertically straight (plumb), compromising the stability and safety of your entire storage system.

More specifically, level racking is essential for keeping your inventory secure, your workers safe from toppling items, and your bottom line intact. To achieve this, you’ll need the right components.

Cue pallet rack shims. These small but mighty steel plates help correct uneven flooring and ensure that your uprights stay vertical.

Here, we explain when and how to level a pallet rack. Keep reading to learn why plumbness matters and the role of pallet racking shims in this crucial alignment.

What is rack plumbness?

![]()

Before we explain how to level pallet racking, we need to talk about plumbness. This refers to the correct vertical alignment of the uprights in a storage racking system.

When a rack is “plumb,” its upright posts are perfectly straight and aligned vertically, ensuring stability, strength and even weight distribution. An upright is considered “out-of-plumb” if it leans in any way, including:

- Cross-aisle direction: The upright tilts forward or backward relative to the aisle, causing instability across the width of the rack.

- Down-aisle direction: The upright leans from side to side, along the length of the aisle, which affects stability and load distribution.

Keeping racking systems plumb is key to maintaining structural integrity, preventing accidents and protecting products and workers.

What causes out-of-plumb pallet racking?

All kinds of factors can lead to misaligned pallet racks. Potential reasons why your racks are no longer perfectly vertical or straight include:

- Beam height adjustments or modifications: Altering the height of beams after the initial setup can disturb the structural integrity, leading to misaligned uprights.

- Type of beam connections: The design and type of beam connection used in the racking system can influence stability. Certain connections may not provide enough flexibility or strength, causing the uprights to tilt or bend over time.

- Loose bolts during installation: If bolts are not adequately tightened when assembling the rack, the structure can shift over time, causing it to lean or curve.

- Forklift or pallet impacts: Accidental collisions at the base of the uprights, often caused by forklifts or mishandled pallets, are a common cause of misalignment. Even minor impacts can gradually affect the plumbness of the entire system.

- Overloading racks: When racks are loaded beyond their designed capacity, it can put excessive stress on the beams and uprights, causing them to bend or shift from their original position.

- Uneven floors: Installation on an uneven surface can cause racks to tilt from the start. This is common when setting up on floors that aren’t perfectly level, such as older or damaged concrete surfaces.

What is a pallet rack shim?

![]()

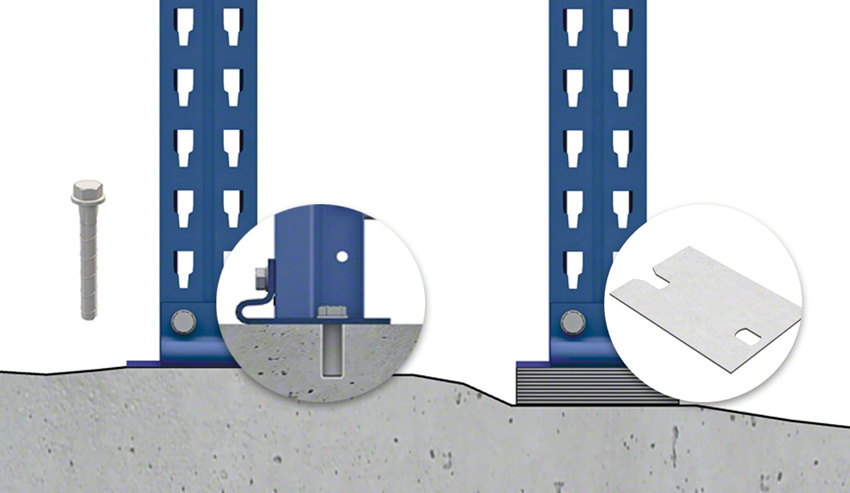

A pallet rack shim is a specialised metal plate designed to fit beneath the base of an upright, helping to ensure the rack is perfectly vertical and stable. These shims level racks when floors are uneven, filling in any gaps between the floor and the upright to achieve balance and eliminate wobble.

While shims come in various materials, sizes, and designs, they must match or exceed the size of the upright baseplate.

Additionally, the shim material must be strong enough to meet the floor’s allowable bearing strength. That way, the entire racking system can remain secure and safe.

RMI guidelines for racking shims

![]()

When uneven flooring requires multiple shims to level your pallet racks, it’s important to follow the Rack Manufacturers Institute (RMI) guidelines. Improper use of shims can lead to shifting and wobbling, which could compromise the entire racking system.

Here’s what you need to know:

- The total height of your shim stack should never exceed six times the diameter of your largest anchor bolt.

- For shim stacks less than twice the diameter of the anchor bolt, you don’t need to weld the shims together or add extra support.

- If the shim stack is between two and six times the diameter of the anchor bolt, you must lock the shims in place. This can be done by welding them together or installing a second anchor. Without securing the shims, they may rotate or slip, jeopardising the rack’s stability.

- In cases where thicker shim stacks are required, you may need to use longer anchor bolts so the system is firmly secured.

By sticking to these RMI guidelines, you can keep your racking system stable and secure, even on uneven floors.

How to level racking with pallet rack shims

Ensuring pallet racking is level is essential for its stability, safety, and load-bearing capacity. While the exact process may vary depending on your site conditions and racking system, here’s a general outline of how to do it with pallet rack shims:

1. Prepare the area

First things first, inspect the floor. Before installation, check that the floor surface is flat and free of debris. Any cracks or uneven sections should be noted, as they may impact the stability of the racks.

2. Install the uprights

Position the first upright. Stand the first upright frame in place, ensuring it is positioned according to the floor plan.

Afterwards, check for initial plumbness. Using a spirit level, check both the side-to-side and front-to-back alignment of the upright. Ensure that it is roughly vertical before making fine adjustments.

3. Adjust the uprights with pallet rack shims

If the floor is uneven, insert pallet rack shims under the baseplate to level the upright. Start by adding shims at the points where the level shows the upright is leaning.

Then re-check the plumbness. Use the spirit level again to check the upright’s vertical alignment. Continue adjusting the number or thickness of racking shims until the upright is perfectly vertical.

4. Tighten base plate anchors

Once the upright is level, securely anchor the baseplate to the floor using appropriate bolts. Tighten the anchors to hold the upright in place, but don’t over tighten before verifying the level of the entire rack.

5. Install and level the remaining uprights

![]()

For the remaining uprights, repeat the same procedure—position the upright, check with the level, adjust with shims, and tighten the base plate anchors. Be sure to align each upright with the first one for consistency.

Next, cross-check alignment. After each upright is levelled, step back and ensure that all uprights are aligned with one another across the row. Remember, a slight misalignment can impact the entire system’s integrity.

6. Install beams and recheck the level

Now install the beams. Attach the horizontal beams to the uprights at the desired height. Make sure that they are securely connected as per the manufacturer’s specifications.

Once the beams are in place, use the spirit level to check for any final adjustments needed on the overall plumbness of the rack. If required, adjust the pallet rack shims slightly and retighten the base plate anchors.

7. Final inspection

Lastly, inspect the entire system. Walk around the racking system, examining both the plumbness of each upright and the evenness of the beams. Ensure that all anchors are securely tightened and the racks are stable.

Once everything is level and secure, load a few test items onto the rack to check stability. Ensure the weight is evenly distributed and no further adjustments are necessary.

Benefits of levelling your pallet rack

Now that you understand how to level racking using pallet rack shims, let’s look at the benefits of doing it right. Here’s why ensuring your racks are perfectly plumb is so important, especially when faced with uneven floors.

Structural stability

Racks that are properly plumb are far more stable, especially under heavy loads. An uneven floor can cause racks to tilt or lean, which compromises their structural integrity. If left unchecked, this instability can lead to a collapse or cause other racks to fail, risking damage to inventory and equipment.

Balanced load distribution

![]()

When racks are out-of-plumb, the weight they carry is unevenly distributed, putting extra strain on certain sections. This uneven load can bend or warp the racking over time, reducing its strength and increasing the chance of failure. Keeping your racks plumb ensures weight is distributed evenly, preserving the integrity of the system.

Sufficient flue space

Flue space—the vertical gaps between racks for ventilation and fire suppression—is a critical part of warehouse safety. Properly plumb racks ensure that this space remains clear and consistent.

If your racks are leaning, the flue space can become obstructed, restricting airflow and fire suppression efforts. This not only violates safety codes but also puts your warehouse at greater risk in an emergency.

Accident prevention

Out-of-plumb racks on uneven floors are more prone to tipping or shifting, increasing the risk of accidents. From falling products to entire racks collapsing, these hazards can cause serious injury to employees and damage to inventory.

Ensuring your racks are level and stable helps to prevent these accidents and create a safer working environment.

Longer lifespan

Racks that remain plumb and stable experience less wear and tear. When all the components are aligned correctly, there’s less strain on bolts, beams, and uprights, which prolongs the life of your racking system. This curbs the need for expensive repairs or replacements.

More storage space

Plumb racks allow you to make the most of your warehouse’s vertical space. Keeping your racks level and upright ensures that your storage system is not only safe but also as efficient as possible.

Discover robust and reliable pallet racking in Sydney

Levelling pallet racking is crucial for warehouse safety and efficiency – and pallet rack shims play a key role in this process. Shims help correct uneven floors, helping each upright stay perfectly vertical.

That way, your racking can remain stable and aligned, which brings invaluable benefits to your business. Properly levelled racks with the support of shims not only protect inventory but also create a safer, more productive workspace while minimising long-term repair costs and downtime.

At Pallet Racking Sydney, we provide strong, cost-effective and customised pallet racking solutions to meet your unique needs. Our end-to-end range includes Schaefer selective racking, racking beams, cantilever racking, longspan shelving and racking accessories.