Pallet racking systems are essential to efficient warehouse storage. And beams are their backbone. These horizontal structures bear the load of pallets, boxes, and various goods, ensuring your inventory is secure, stable and easily accessed.

There are various pallet rack beam types to choose from, and selecting the right one for your operations is key to designing a safe and efficient storage solution.

Here, we unpack the different types of pallet racking beams, including their distinct features and benefits. Keep reading to learn which design is ideal for your warehouse setup.

What are pallet rack beams?

A pallet rack beam is the horizontal load-bearing support that links the vertical frames in a racking system.

These firm beams reinforce the structure and support pallets by evenly distributing their weight across the racks. This helps to ensure stable storage and safe material handling during loading and unloading operations.

Beams come in a variety of styles, heights, lengths and gauges. The optimal pallet rack beam type for your warehouse depends on the size of the racking system, as well as the weight and dimensions of stored goods.

![]()

Pallet rack beam features

Pallet rack beams are typically made of steel so that they are robust enough to hold heavy loads.

These beams attach to the uprights through endplates that slot into the posts for lasting stability. Safety pins on the endplates help prevent the beams from accidentally dislodging during equipment handling.

It’s also easy to remove and reorganise warehouse racking beams as required. These components are also adjustable, allowing them to be positioned at various heights along the vertical frames to cater to different pallet sizes and operational needs.

Thanks to this flexibility, pallet racks can often store much more than standard pallets, including containers, boxes and even loose packages.

To securely hold these goods, beams may need to be accompanied by racking accessories like shelving or other supports.

Why is it important to use the right beams?

![]()

Using the right pallet rack beam type is absolutely critical to the stability, safety and efficiency of your warehouse storage system.

If you use a beam with the wrong load capacity or design, it will compromise the entire racking structure’s integrity. A collapse could damage goods, injure workers and bring costly downtime.

That’s why, along with frames and other pallet rack components, beams must meet AS 4084-2023 Steel Storage Racking.

Under this industry standard, signage must detail the:

- Total working unit load limit per pallet beam level;

- Maximum distance between the base plate level and first beam level; and

- Maximum distance between adjacent beam levels.

Importantly, clearance from the top of a pallet to the underside of the load beam above it must equal or exceed:

- 75mm for pallet rack beams under 6.0m; and

- 100mm for pallet rack beams over 6.0m.

The most common pallet rack beam types

![]()

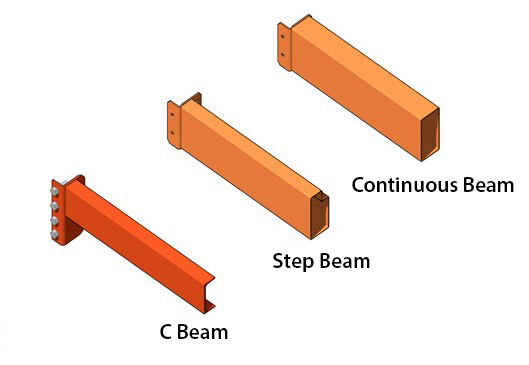

1. C beams

C beams, also called channel beams, feature a curved cross-section. These pallet rack beams are made by hot roll forming raw steel into the characteristic channel shape.

With double C beams, two C-shaped profiles are welded together for exceptional strength and load-bearing capacity.

Ideal for heavy loads, double C beams are great for storing pallets or boxes on slatted timber decking. On the other hand, they aren’t the most space-efficient option for storing light or medium loads.

For shorter lengths and lighter inventory, single C beams may be more suitable. Moreover, the hollow design allows you to attach various accessories that cannot be affixed to double C beams.

Importantly, you can adjust the height of C beams. Combined with a wide variety of lengths, widths and capacities, this type of pallet rack beam suits practically any unit load.

2. Step beams

Step beams are engineered to connect securely to uprights for safe and dependable pallet storage. They are usually used for storing lighter loads than double C beams.

Constructed from a single piece of roll-formed steel, step beams feature a ledge with welded end plates that fit into the teardrop-shaped holes on the frame face.

This ledge is designed to support wire mesh decks, clip-in pallet bars, drop-in panels and other solid materials. It helps maintain a flat storage surface and keeps supports flush with the top of the beam.

A load level has two step beams, with one placed at each frame post. The beam is fastened to the frames with a spring-loaded safety lock on each endplate.

3. Z beams

As the name suggests, Z beams feature a Z-shaped profile. Sometimes, these pallet rack beams have an upper flange that serves as a stop for wooden supports.

Ideal for picking applications, these beams are designed to accommodate metal or wooden panels that store manual goods and cartons.

Therefore, they typically have a lower load capacity.

4. Continuous beams

Clad-rack warehouses incorporate pallet racking into the building’s structural design.

Sound like the right fit for your facility?

Often, you’ll need continuous beams to create this kind of storage system.

These very long beams don’t feature connectors, instead spanning various structure modules. The extra length and multiple supports typically make continuous beams more efficient.

That said, their positioning is set in place, so their levels can’t be adjusted.

While the least common of all pallet rack beam types, we’ve got your continuous beams covered. Our expert team can design, manufacture and install any sort of racking beam in Sydney.

Explore complete pallet racking systems in Sydney

Pallet rack beams are crucial components of any racking system, supporting the unit load safely and securely. Now that you know the difference between common pallet rack beam types in Australia, it’s time to sort out your warehouse storage.

Discover robust racking beams with Pallet Racking Sydney. We offer affordable, durable and customised pallet racking solutions, and can help with selections if you’re not sure which beams are best for your warehouse.

Our comprehensive range includes Schaefer selective racking, cantilever racking, longspan shelving and racking accessories.