A messy warehouse can spell problems for your business in a large number of ways. The chances of workplace injuries because of a bad warehouse are magnified in this instance. Placing employees at risk can also be a major liability for your business. Every business has a responsibility to provide its employees with a safe environment where they are not likely to face injuries of any sort.

A large number of workplace problems can actually be sorted out by focusing on improving your warehouse. Improving your warehouse doesn’t mean that you get a new one; it just means changing a few core areas to get drastically improved results. The following are a few major ways in which you can improve the functionality of your warehouse with ease.

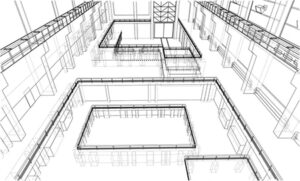

Optimise the layout

The first step to improving your warehouse is by having a good look at the layout. You should actively re-evaluate it and plan it based on optimization for scalability as well as flexibility in usage. When you are examining the layout, try to find the answers to various questions such as:

- Are your workers running from one end of the warehouse to the other to get items they need?

- Is there enough storage?

- Is the pallet racking in the warehouse difficult to access?

- Are there chances of bumping into shelving?

- Are the raised flooring platforms dangerous?

All these things and more should be considered and answered. You want your warehouse to allow you to work faster and smarter in a safe manner. Luckily, with floor optimization, you can have a layout that is functional, safe and helps make you more productive instead of vice versa. You can also maximize the usability of the warehouse in this manner, which is beneficial for everyone involved.

Safer flooring

Slips and accidents by falling are among the highest in warehouses, which is why you need to focus on having safe flooring options. Around 25% of all workplace injuries occur in warehousing, transport and postal industries in Australia. In fact, 14% of work casualties or fatalities are because of slips and falls and can occur to individuals of any age or gender. The good news is that the numbers for work place casualties can be brought down by just making your raised storage platforms more secure.

It might not appear like a major factor, but take the time to evaluate the safety of your raised storage platforms you have in your warehouse. One of the best options can be to opt for improved security by adding handrails and staircases. These can be treated to make the flooring slip-proof and to prevent any accidents. The best part is that mezzanine flooring safety measures are also customizable, extremely cost effective and reusable as well, which makes them perfect for scalability and future growth of the warehouse and the business.

Make good use of available space

When you are using mezzanine flooring options such as raised storage platforms for the warehouse, you will be able to get more available space. In fact, this is one of the biggest benefits of this kind of flooring for your warehouse. Not only does this flooring give you more space, it also allows you to effectively utilize the available space you have without requiring any extensive makeovers that come with high costs.

Mezzanine flooring can be paired with other features such as handrails, staircases and vertical pallet racking, which helps to improve the storage options for your warehouse. Used in conjunction with each other, you can easily ensure that you have a warehouse that is functional, has good storage options and is not cramped or a safety and security hazard for anyone. The chances of workplace injuries can also be minimized in this manner and all available space can be utilized properly.

Automation can help

Another way that you can improve the functionality of your warehouse is by making use of automation in it. Automation means making use of the Internet of Things to simplify various functions. This can be anything from having a central temperature control for your cold storage warehouse to having robotic forklifts that simplify packing, stacking and using the pallet racking without any chances of accidents.

Inventory can also be kept properly with the help of automation as it can make it easier to sort through the various pallet racking shelves in the warehouse. This also reduces the need to manually handle each pallet racking shelves, or the boxes, cartons and more stored there. Not only does an automated warehouse save you time and streamline your business, it also greatly reduces the chances of workplace injuries as well.

Organisation in workstations

A disorganized workstation in the warehouse can lead to bigger chances of workplace injury as well as ruin productivity. Make sure that the workstation is easily accessible, uncluttered and storage is nearby as well. If one has to run from one end of the workhouse to the other to get something in a pallet racking, it can waste them time which makes it longer for them to finish a task efficiently. Moreover, disorganization can contribute to workplace injuries as well.

With mezzanine flooring options in warehouses, you can define workstations as well as separate the warehouse storage areas from them. The best part about using this option is that mezzanine flooring allows you to make offices, separations and more within the available space of the warehouse. You don’t have to worry about the fixtures as well since mezzanine flooring can be customized and is compatible with a large number of features for different facilities.

Improved storage options

One of the major problems in warehouses can be the limited storage options available. Luckily, by adding some mezzanine flooring as well as some vertical pallet racking, you can drastically improve the storage options in your warehouse. Picking the right racking is necessary as storage accidents can also happen, which can cause serious workplace casualties or fatalities.

Vertical pallet racking works much like shelving does and can be used skilfully to ensure that you are able to maximize the storage available in the space. The best part is that pallet rackings have been used for years and are known for being functional, cost-effective as well as flexible to use. They also have a lot of storage abilities. You can also make use of various shelving options that are smaller than pallet rackings but also double up the available storage space with ease.